1. Characteristics

Nolato 8940 is a conductive silicone rubber under development.

? A two-component thermal cure silicone filled with conductive Ni/C particles.

? It is used to produce integrated EMI shielding gaskets by dispensing and Trishield 2.0 forming directly on telecom or other industrial components.

? The patented Trishield gasket* offers a triangularly shaped gasket with improved shielding properties.

? Low viscosity offers short cycle times in any dispensing machine.

? Excellent shielding combined with good mechanical properties.

? The aluminium compatible conductive filler offers enhanced galvanic corrosion resistance and stability in severe environments.

? Operating temperatures between -55°C and +125°C.

? Good adhesion to most metal and metallised surfaces.

? Typical gasket height from 1,2 mm and up to about 3 mm.

? Recommended compression between 10 and 50%.

2. Applications

? Nolato 8940 is particularly suitable for low cost production of gaskets on large series of aluminium castings when there is a demand of excellent shielding and an extra soft gasket

? Typical application is dispensed EMI shielding gaskets

3. Processing

Nolato 8940 is a two-component compound of pasty consistency. The component A and B are delivered in 1000 ml cartridges with a shelf life of at least 6 month if stored at –18°C. The components are mixed in a ratio of 1:1 by weight prior to use. The mixed material is dispensed as a bead directly on the component with a standard dispensing machine. The dispensed gasket is given a narrow shape in the Trishield 2.0 forming unit. Curing is done in a hot air oven at 150°C for 30 minutes. For detailed information please refer to the “Mixing and handling instruction”.

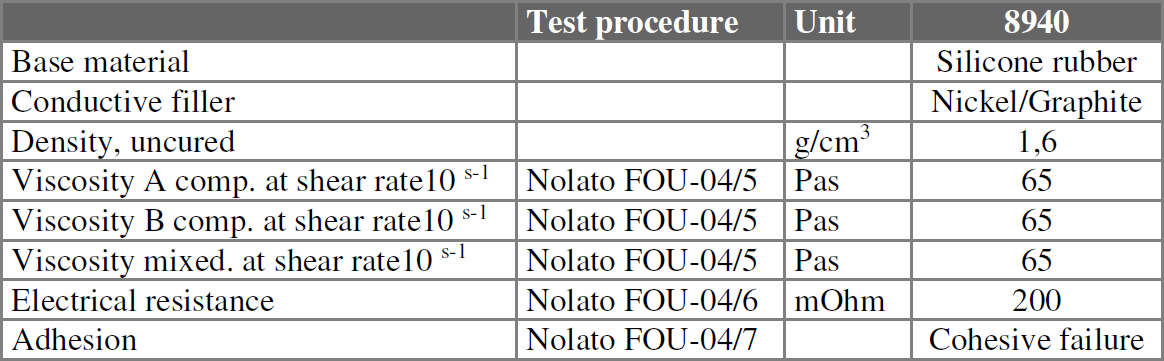

4. Product data

* Production of Trishield gaskets requires a license from Nolato. The licence includes rights to produce and market Trishield gaskets and technical support and the special forming unit.

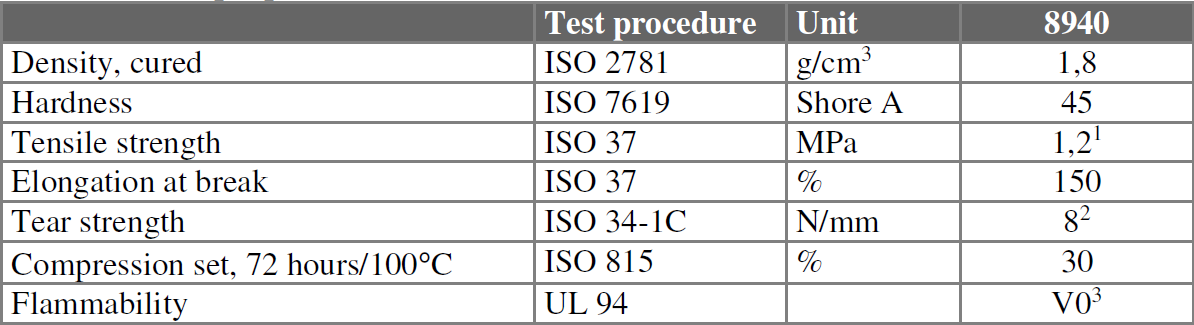

5. Mechanical properties

1 1 MPa = 145 psi 2 1 N/mm = 5,71 lb/in

3 Tested on a 0,8 mm thick gasket adhered to an aluminium substrate with a thickness of 2 mm.

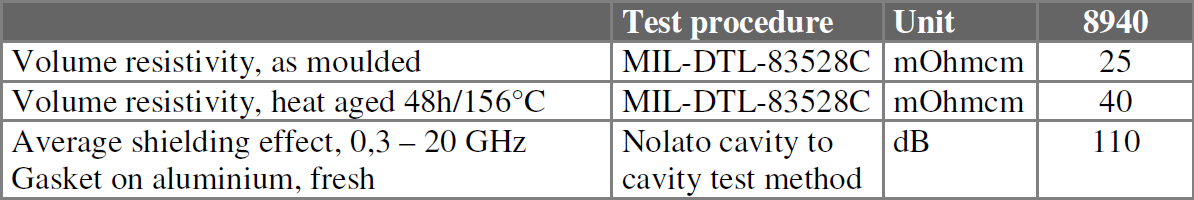

6. Electrical and shielding properties

7. RoHS information

Nolato 8940 fulfils the requirements set by the EU Directive 2011/65/EU (RoHS).

8. Safety instructions

Nolato 8940 is according to EU directive 1272/2008 (CLP) classified as harmful, class Xn, due to the content of nickel. Nickel may cause sensitisation by skin contact. It is advisory to never touch the gasket without gloves. A material safety data sheet can be sent on request.

9. Warranty

The data given in this product information should be taken only as a guide and not a specification. Data are based on statistical evaluation on data measured on a number of batches at Nolato.

The recommendations and data given are based on our experience to date, however, no liability can be assumed in connection with their usage and processing.

Room 101, Back Bungalow, No. 376, Huangpu East Ring Road, Huangpu Community, Xinqiao Street, Baoan District, Shenzhen

Tel:0755-27909926/0755-27909936

E-mail:walter_coco@163.com

?2019 深圳市星河達(dá)科技有限公司 版權(quán)所有 粵ICP備19042287號(hào)